With passive and active cell balancing, each cell in the battery stack is monitored to maintain a healthy battery state of charge (SoC). This extends battery cycle life and provides an added layer of protection by preventing damage to a battery cell due to deep discharging because of overcharging. Passive balancing results in all battery cells having a similar SoC by simply dissipating excess charge in a bleed resistor; it does not, however, extend system run time. Active cell balancing is a more complex balancing technique that redistributes charge between battery cells during the charge and discharge cycles, thereby increasing system run time by increasing the total useable charge in the battery stack, decreasing charge time compared with passive balancing, and decreasing heat generated while balancing.

Active Cell Balancing During Discharge

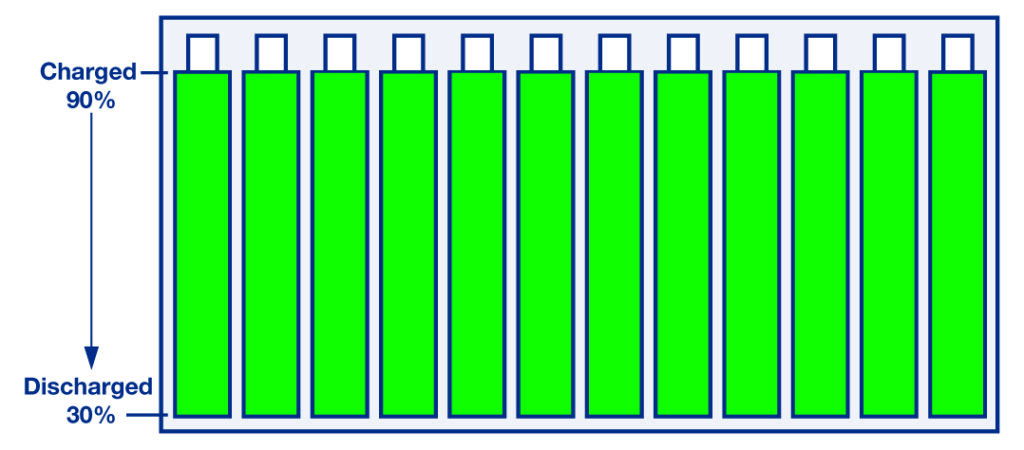

The diagram in Figure 1 represents a typical battery stack with all cells starting at full capacity. In this example, full capacity is shown as 90% of charge because keeping a battery at or near its 100% capacity point for long periods of time degrades its lifetime faster. The 30% discharge represents being fully discharged to prevent deep discharge of the cells.

Figure 1. Full capacity.

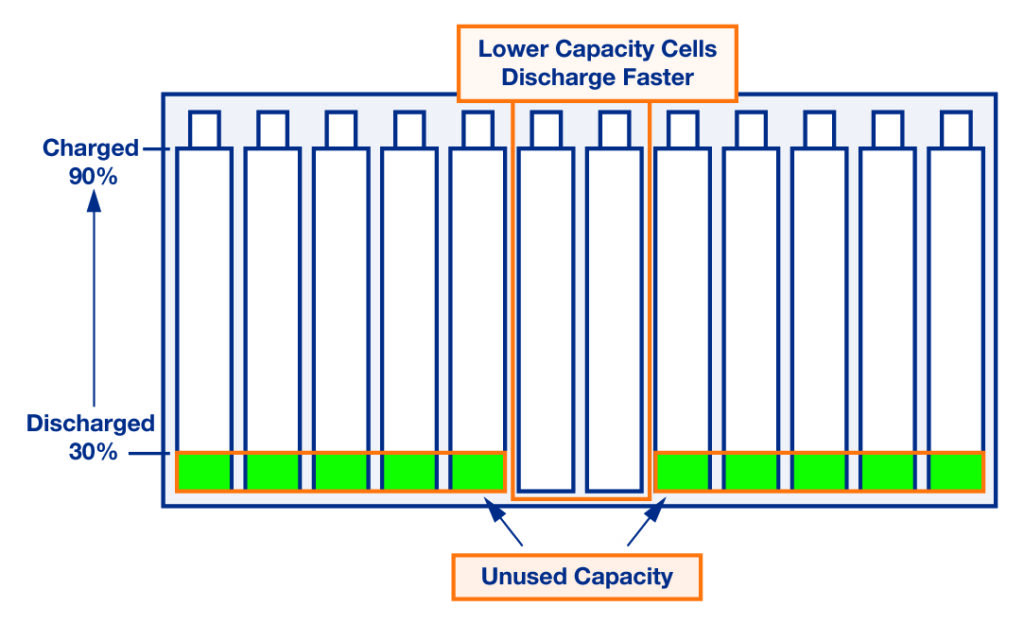

Over time, some cells will become weaker than others, resulting in a discharge profile, as represented by Figure 2.

Figure 2. Mismatched discharge.

It can be seen that even though there may be quite a bit of capacity left in several batteries, the weak batteries limit the run time of the system. A battery mismatch of 5% results in 5% of the capacity being unused. With large batteries, this can be an excessive amount of energy left unused. This becomes critical in remote systems and systems that are difficult to access. As a result, there is a portion of energy that cannot be used, which results in an increase in the number of battery charge and discharge cycles. Furthermore, this unused energy reduces the lifetime of the battery and leads to higher costs associated with more frequent battery replacement.

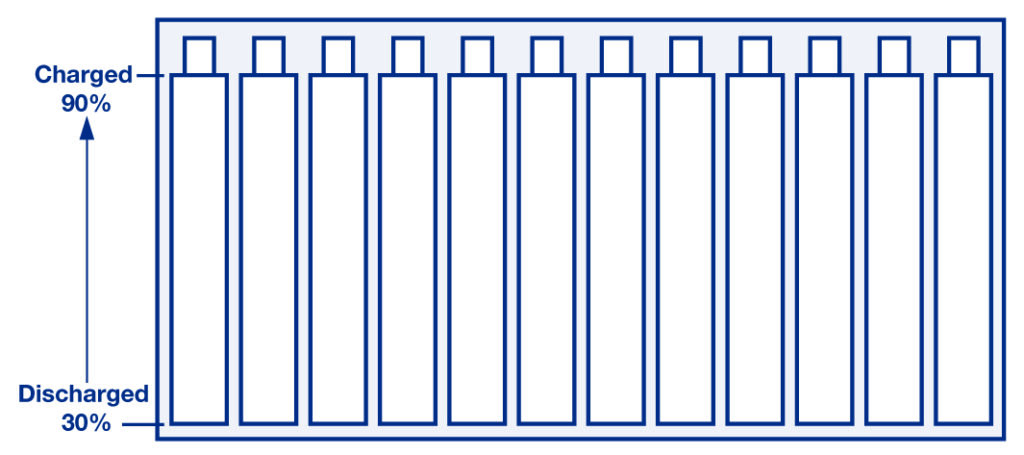

With active balancing, charge is redistributed from the stronger cells to the weaker cells, resulting in a fully depleted battery stack profile.

Figure 3. Full depletion with active balancing.

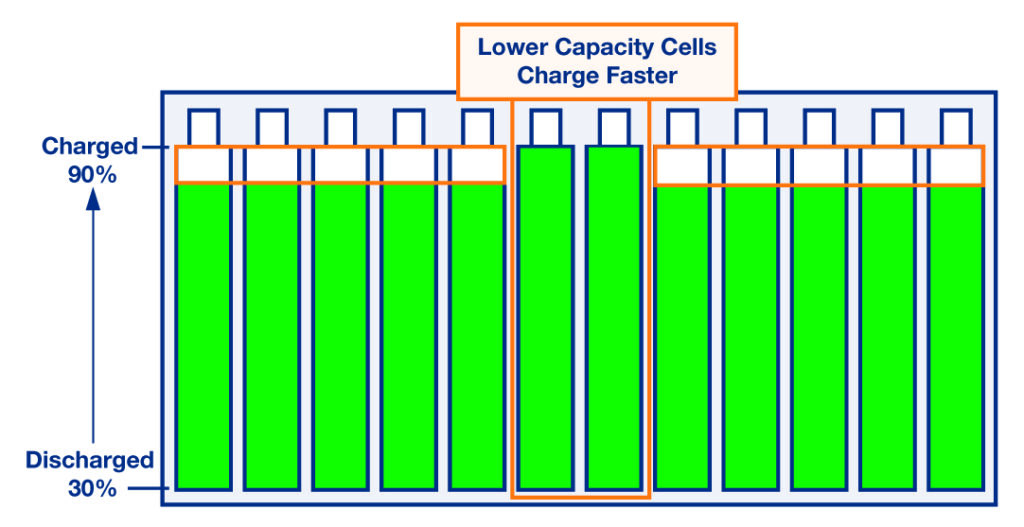

Active Cell Balancing While Charging When charging the battery stack without balancing, the weak cells reach full capacity prior to the stronger batteries. Again, it is the weak cells that are the limiting factor; in this case they limit how much total charge our system can hold. The diagram in Figure 4 illustrates charging with this limitation.

Figure 4. Charging without balancing.

With active balancing charge redistribution during the charging cycle, the stack can reach its full capacity. Note that factors such as the percentage of time allotted for balancing and the effect of the selected balancing current on the balancing time are not discussed here, but are important considerations.

Figure 5. 12 cell battery stack module with active balancing.

Analog Devices Active Cell Balancers

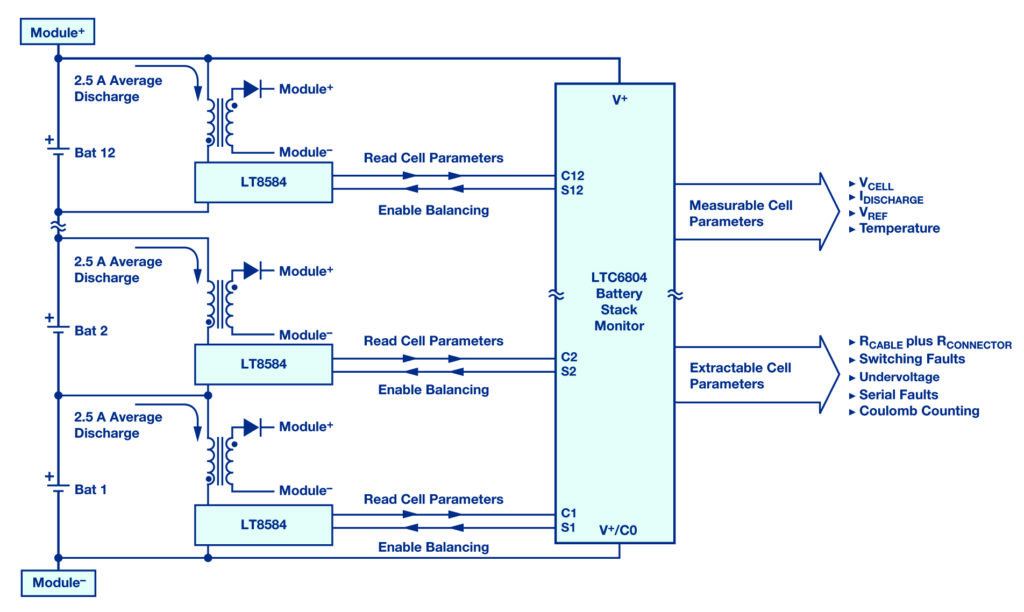

Analog Devices has a family of active cell balancers, with each device targeting different system requirements. The LT8584 is a 2.5 A discharge current, monolithic flyback converter used in conjunction with the LTC680x family of multichemistry battery cell monitors; charge can be redistributed from one cell to the top of the battery stack or to another battery cell or combination of cells within the stack. One LT8584 is used per battery cell.

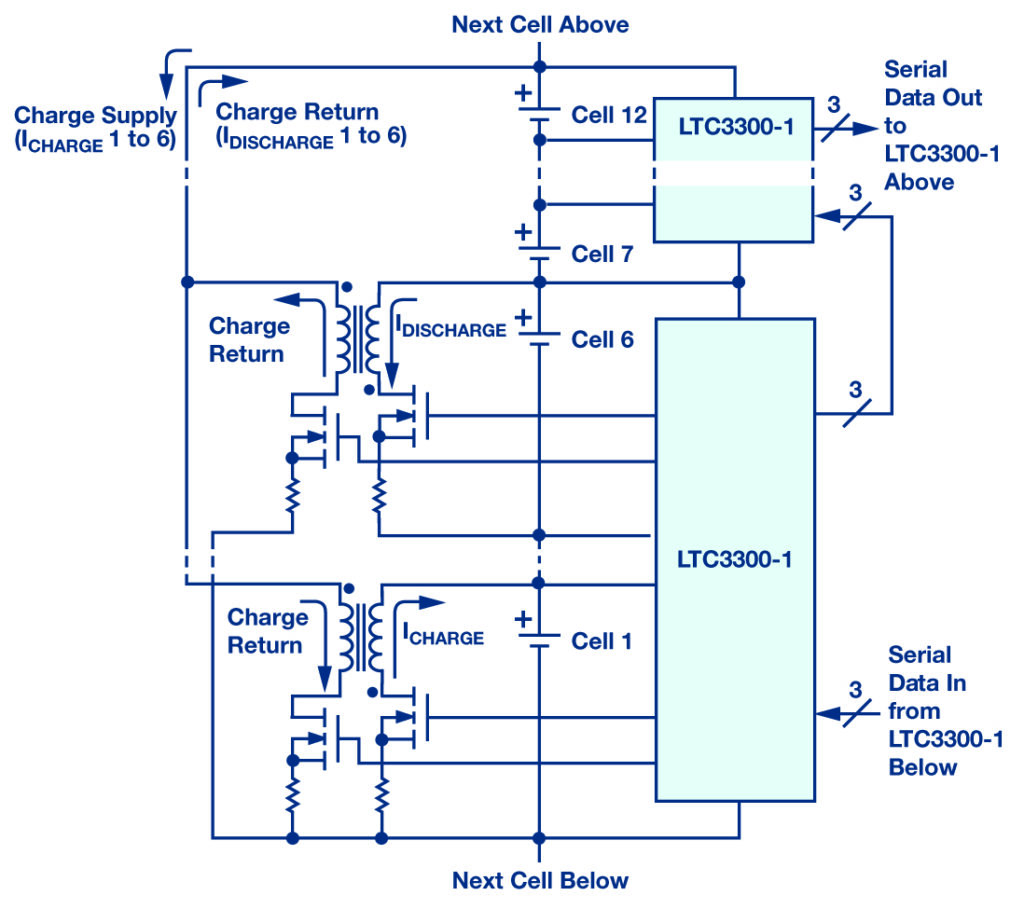

The LTC3300 is a standalone bidirectional flyback controller for lithium and LiFePO4 batteries that provides up to 10 A of balancing current. Since it is bidirectional, charge from any selected cell can be transferred at high efficiency to or from 12 or more adjacent cells. A single LTC3300 can balance up to six cells.

Figure 6. High efficiency bidirectional balancing.

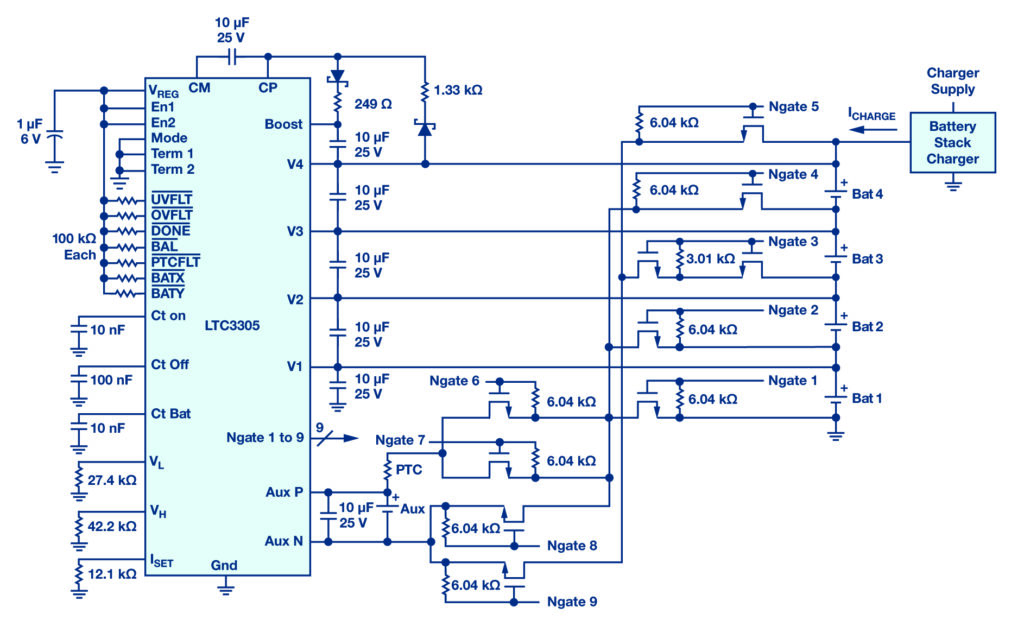

The LTC3305 is a standalone, lead acid battery balancer for up to four cells. It uses a fifth reservoir battery cell (Aux) and continuously places it in parallel with each of the other batteries (one at a time) to balance all battery cells (lead acid batteries are rugged and can handle this).

Figure 7. Four battery balancer with programmed high and low battery voltage fronts.

Conclusion

Both active and passive cell balancing are effective ways to improve system health by monitoring and matching the SoC of each cell. Active cell balancing redistributes charge during the charging and discharging cycle, unlike passive cell balancing, which simply dissipates charge during the charge cycle. Thus, active cell balancing increases system run time and can increase charging efficiency. Active balancing requires a more complex, larger footprint solution; passive balancing is more cost effective. Whichever method works best in your application, Analog Devices offers solutions for both, which are integrated into our battery management ICs (such as the LTC6803 and LTC6804) and complementary devices that work in conjunction with these ICs to provide a precise, robust battery management system.

About the Authors

Kevin Scott works as a product marketing manager for the Power Products Group at Analog Devices, where he manages boost, buck-boost and isolated converters, LED drivers, and linear regulators. He previously worked as a senior strategic marketing engineer, creating technical training content, training sales engineers, and writing numerous website articles about the technical advantages of the company’s broad product offering. He has been in the semiconductor industry for 26 years in applications, business management, and marketing roles.

Kevin graduated from Stanford University in 1987 with a B.S. in electrical engineering and started his engineering career after a brief stint in the NFL. He can be reached at kevin.scott@analog.com.

Sam Nork joined Linear Technology (now part of Analog Devices) as a senior product engineer at the company’s Milpitas, CA headquarters in 1988. In 1994, he relocated to the Boston area to start up and manage an analog IC design center where he continues to work today. Sam has personally designed and released numerous integrated circuits in the area of portable power management, and is inventor/co-inventor on seven issued patents. As director of ADI’s Boston Design Center, Sam leads a team of nearly 100 people and oversees day-to-day development activity for a wide variety of analog integrated circuits in areas including portable power management, high speed op amps, industrial ADCs, system monitors, and energy harvesting. Previously, Sam also worked for Analog Devices in Wilmington, MA as a product/test development engineer. He received A.B. and B.E. degrees from Dartmouth College. He can be reached at samuel.nork@analog.com.